Comparison of the Advantages of a 3/8" LP Saw Chain vs. a Standard 3/8'' Saw Chain

1. Low-Profile Design Reduces Weight and Increases Cutting Speed

"LP" stands for Low Profile. Its rakers are shallower than those in a standard 3/8'' chain, resulting in a lighter overall chain weight and enabling higher speeds on saws with the same horsepower, improving cutting efficiency.

Compared to a 3/8'' chain, the 3/8''LP chain has a cutting area of only 120㎡ , compared to 180 ㎡ for a 3/8'', meaning it requires less effort and is easier to operate during light-duty operations.

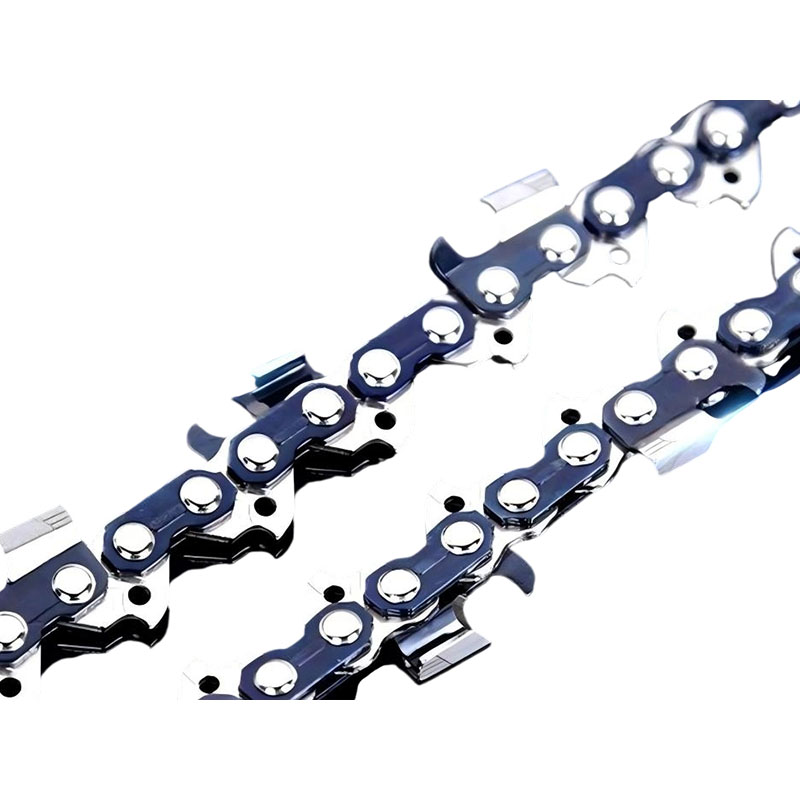

2. Smooth Cutting and Lower Friction

The full chisel cutting teeth are designed to reduce cutting friction, resulting in "extremely smooth, clean cutting and rapid chip clearing," particularly at high speeds under clean conditions. Low-profile chains offer approximately 30%–40% less cutting resistance than traditional chains, improving not only work efficiency but also significantly reducing vibration and noise during operation, enhancing safety.

3. Easy Maintenance and Manageable Lifespan

Due to the chain's light weight and simplified tooth profile, daily maintenance (such as cleaning and oiling) is more convenient, making it suitable for intermittent use by home users and gardening enthusiasts.

By optimizing processes and materials, Hengjiu has achieved a "durable and affordable" product positioning, further reducing replacement costs.

4. Strength and Safety

With the same chain thickness, the maximum tensile force of a 3/8" LP chain is approximately 2.85kN. While lower than the 5.13kN of a standard 3/8" chain, it's sufficient for light-duty garden pruning. Furthermore, its lighter weight provides greater chain flexibility, reducing the risk of chain breakage.

What are the common signs of wear or damage?

Common Signs of Wear or Damage

1. Cutting Tooth Wear

After 50 hours of continuous or cumulative operation, the wear on the lower edge of the cutting teeth should not exceed 0.4mm. Exceeding this limit will result in reduced cutting efficiency and rough cuts.

2. Drive Link Side Wear

The upper limit for wear on the side of the drive link is 0.3mm. Exceeding this limit will cause chain slack and deviation.

3. Chain Elongation (Chain Elasticity)

The elongation of each chain link should be controlled within 0.15%. Excessive elongation can cause tensioning bolt failure, chain jump, or even breakage.

4. Surface Scratches, Rust, and Cracks

Long-term use or lack of lubrication can cause scratches or rust on the metal surface, further accelerating the development of fatigue cracks, manifesting as increased link gaps, chain plate deformation, or partial fractures.

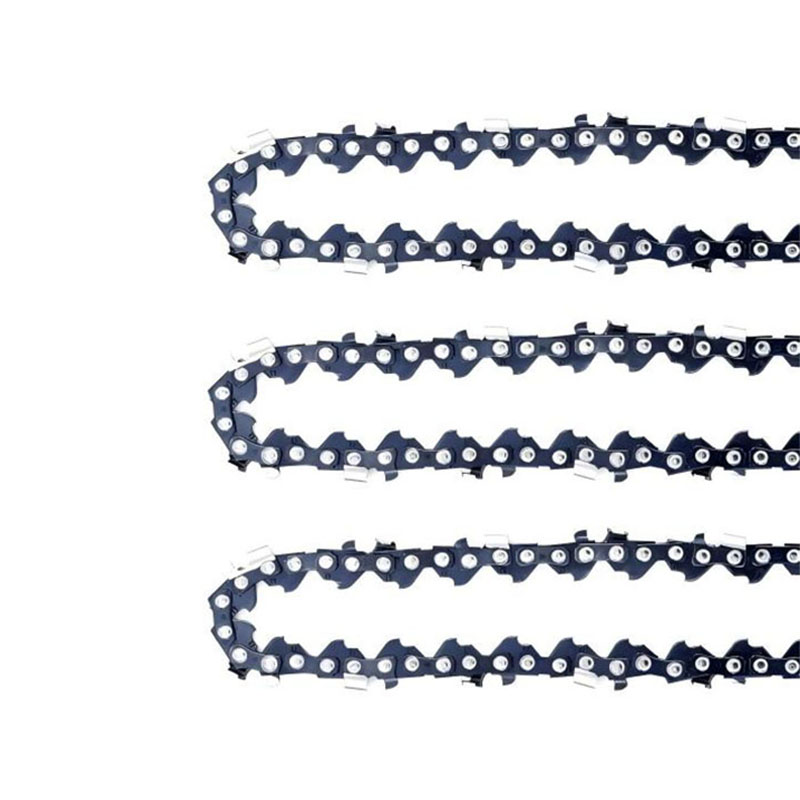

5. Key Visual Inspection Points

Normal Condition: Cutting teeth are sharp and have intact tooth edges; chain links are tightly connected and not loose; the metal surface is bright and free of obvious scratches. Wear symptoms: blunting or chipping of cutting teeth, increased gap between chain links, cracks or deformation of chain plates, and wear marks or rust spots of varying depths on the surface.

English

English

中文简体

中文简体

русский

русский