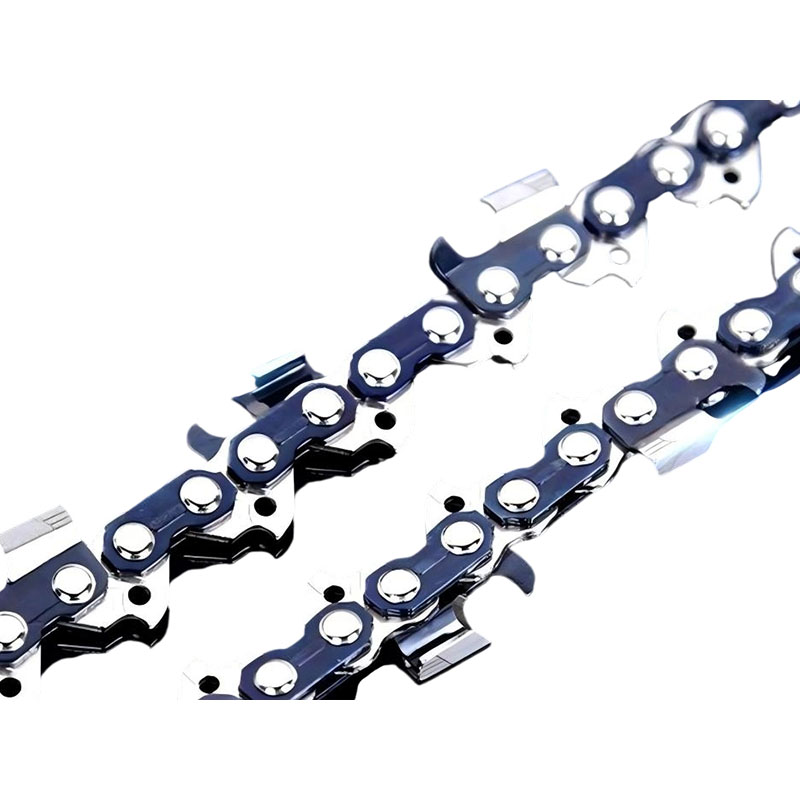

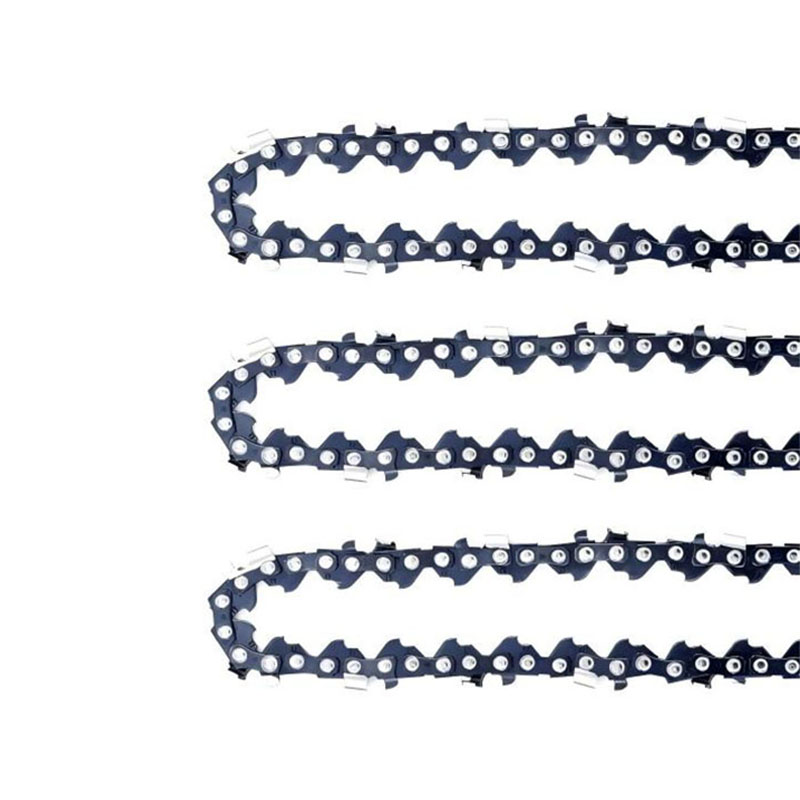

3/8" LP Saw Chain Maintenance Tips

1. Clean the chain and guide bar regularly.

Use a soft brush or a specialized cleaner to remove resin, wood chips, and metal shavings from the chain surface to prevent increased wear.

After cleaning, check the guide bar grooves for blockage to ensure smooth chain operation.

2. Maintain proper lubrication.

Continuously apply lubricant according to the manufacturer's recommended amount to ensure an even film of oil between the chain and guide bar.

Use specialized chain oil or an automatic lubrication system to avoid chain jams caused by oil of an inappropriate viscosity.

3. Regularly check and adjust the tension.

Use the "snapshot test" to confirm that the chain is slightly lifted in the middle of the guide bar, with only approximately three drive links exposed. If the chain is too loose or too tight, adjust it immediately.

After adjustment, perform the snapshot test again to ensure that the chain is running without slippage or stress.

4. Timely Grinding and Replacement

Low-profile chains have relatively weak cutting teeth. Use a dedicated whetstone or grinder to keep them sharp.

When chain teeth are worn beyond recovery or the depth gauge shows noticeable wear, replace the chain promptly to ensure efficient and safe cutting.

How should the optimal tension of a 3/8" LP saw chain be adjusted to achieve the best balance between cutting efficiency and longevity?

Optimal Tension Adjustment for a 3/8" LP Saw Chain

1. Basic Principles of Tension

The 3/8" LP saw chain should slide freely in the guide bar, with only approximately three links of the drive link visible when viewed from the side. Overtightening increases friction and accelerates wear, while over-loosening can easily cause the chain to come loose.

2. Adjustment Procedure

Turn off the power or engine and use a wrench to loosen the tensioning nut.

Gently turn the tensioning screw until the chain slightly lifts in the middle of the guide bar, ensuring the "snapshot test" passes.

After tightening the tensioning nut, check the chain tension again to ensure there is no visible slack or indentation.

3. Checking Tension Frequency

Perform a visual inspection before and after each use, especially after extended operation or after chain replacement.

Recheck the tension after operating in high temperatures or under high loads to prevent chain loosening due to thermal expansion and contraction.

4. Factors Affecting Tension

The optimal tension setting for a 3/8" LP saw chain can be affected by frequency of use, operating environment (such as humidity and dust), and chain wear.

Properly adjusting the tension can extend chain life and improve cutting efficiency.

English

English

中文简体

中文简体

русский

русский