Common causes of rapid chain stretching or dulling

1. Improper tension causing chain stretching

Over-tensioning increases friction between the chain and guide plates, causing slight stretching of the 3/8'' Saw Chain under high load, leading to chain "slack." Experiments show that overly tight chains significantly increase energy consumption and cutting time.

2. Contact with ground, dirt, or metal debris during cutting

If the chain encounters hard debris such as the ground, dirt, or nails during cutting, the cutting teeth will be immediately damaged and quickly dull.

3. Cutting tooth wear and dulling

With use, the cutting angle of the cutting teeth gradually increases, cutting efficiency decreases, leading to increased cutting resistance and higher fuel or electricity consumption. Studies show that dulled chains can increase traverse cutting time and energy consumption by about 6 times.

4. Insufficient lubrication or use of inappropriate oil

A lack of sufficient lubricant will exacerbate metal-to-metal friction, causing premature chain wear and thermal expansion, resulting in slight chain stretching. How to install or tension a 3/8" saw chain properly?

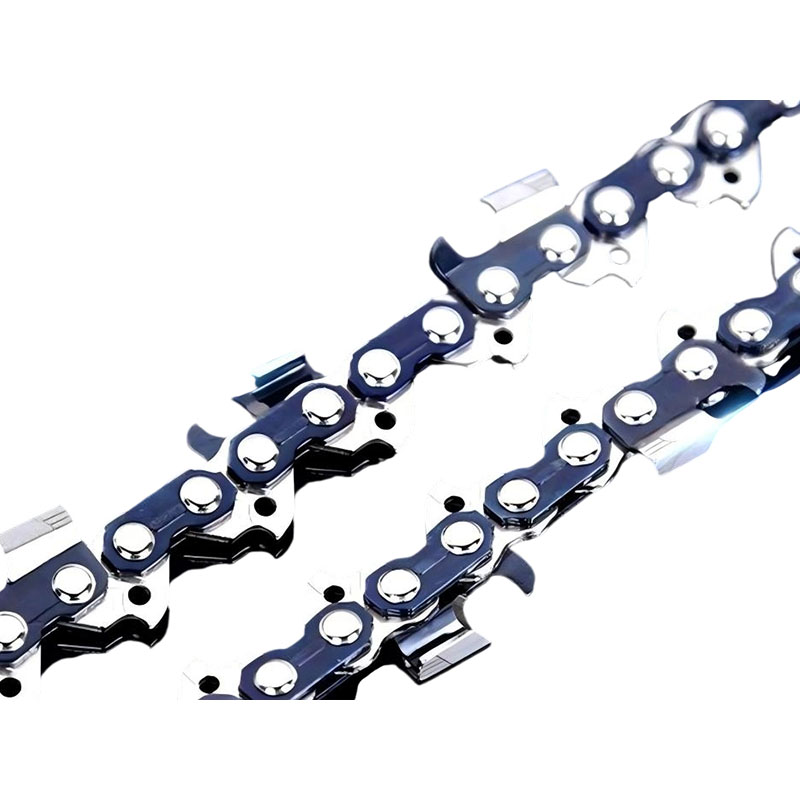

Steps for correctly installing a 3/8"' Saw Chain

1. Preparation

Turn off the power or remove the ignition key to ensure the chainsaw has completely stopped.

Use a wrench (number 17 in the diagram) to loosen the tension screw (number 9) to allow the guide plate to retract, making chain installation and removal easier.

2. Placing the Chain

Evenly place the chain into the guide plate grooves, ensuring the teeth face outwards and both ends of the chain are secured in the grooves on either side of the guide plate.

3. Adjusting the Tension Screw

Gently tighten the tension screw, raising the chain slightly by about 1/8 inch in the middle of the guide plate. At this point, only three drive links should be visible, indicating standard tension.

4. Inspection and Trial Run

Start the chainsaw and observe if the chain runs smoothly. If excessive slack or chain jumping occurs, readjust the tension screw until the "three links visible" standard is met.

Key Points for Properly Tensioning a 3/8'' Saw Chain

1. Snap-Test

With the chainsaw stopped and power off, gently pull the chain with your fingers. If it lifts slightly in the middle of the guide plate, and only three drive links are visible, the chain is properly tensioned.

2. Avoid Over-Tightening

Over-tightening will cause the chain to elongate, accelerate wear, and may damage the tensioning mechanism. In experiments, approximately 1190g of weight is used to simulate over-tightening, but the "three links visible" principle must still be maintained to prevent mechanical damage.

3. Regular Re-inspection

After prolonged use or after replacing the cutter teeth, repeat the Snap-Test to ensure the tension consistently meets the standard.

4. Use Appropriate Lubrication

After each tensioning, evenly spray chain-specific lubricant to maintain good lubrication between the chain and the guide plate, reducing the risk of elongation due to friction and thermal expansion.

Key Details for Maintenance and Care

1. Regularly Clean the Chain

After cutting, use a soft brush to remove sawdust, dirt, and metal shavings from the chain to prevent hard debris from quickly dulling the blades.

2. Sharpen or Replace Promptly

When the blades show significant dulling or wear, use a 5/16″ (approximately 4mm) file to maintain a 30° top plate angle, or send it to a professional sharpening station for resharpening.

3. Check Guide Plate Wear

Significant wear or deformation in the guide plate grooves will affect chain tension and cutting efficiency; replace the guide plate if necessary.

4. Record Usage Time

Record the duration of each use and the type of material cut to help determine when maintenance or chain replacement is needed.

English

English

中文简体

中文简体

русский

русский