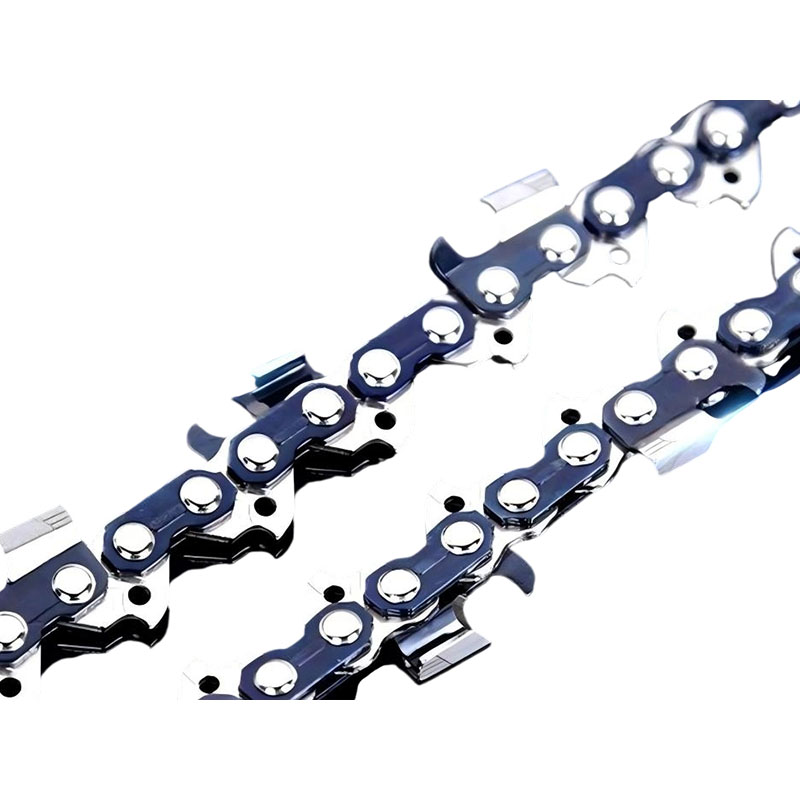

Common 3/8" saw chain materials and heat treatment methods affect their service life

1. Common Materials

Most 3/8" saw chain chains are made of high-alloy tool steel (such as the 0.58" and 0.50" series). Its chemical composition is primarily composed of alloying elements such as carbon, silicon, manganese, chromium, molybdenum, and nickel, ensuring sufficient strength while providing good toughness.

To improve wear resistance, some products feature hard chrome plating or carbide plating on the chain teeth, creating an extremely high surface hardness that significantly slows tooth tip wear.

To meet the demands of low noise and lightweight construction, lightweight chains made of low-alloy steel or high-strength alloy steel are also available, suitable for light-duty operations.

2. Heat Treatment Process

Standard chains must undergo a quenching-tempering heat treatment after forming: first, oil or water quenching at 880-980°C to transform the microstructure into martensite, followed by tempering at 590-640°C to reduce brittleness and increase toughness.

For high-alloy chains, a two-phase heat treatment (high-temperature solution treatment followed by low-temperature tempering) is often used to achieve a more uniform hardness distribution and inhibit segregation of precipitated phases.

Advanced heat treatment techniques (such as laser case hardening) can form an extremely thin, high-hardness layer on the tooth tips, keeping the cutting edge sharp longer while reducing the risk of thermal cracking.

3. Improvements in Hardness and Wear Resistance Through Heat Treatment

Quenching-tempering can increase the chain hardness to 48-55 HRC, significantly improving wear resistance.

Precise control of the tempering temperature determines the balance between hardness and toughness: too low a tempering temperature results in excessive hardness and brittleness; too high a tempering temperature results in insufficient hardness and increased wear. Surface treatments like laser hardening create a tooth tip hardness 4-5 times that of the base, allowing the chain to maintain sharpness even under high-load cutting loads and extending its overall service life.

4. Comprehensive Impact on Service Life

Using high-alloy steel and combining it with appropriate quenching and tempering processes can increase chain service life by 30%-50%.

Surface hard chrome or carbide plating further reduces tooth tip wear, ensuring stable chain performance in harsh environments (such as high temperatures, humidity, and dusty wood).

Improper heat treatment (such as under- or over-tempering) can cause cracks and chipping, significantly shortening chain life. Therefore, manufacturers (such as Hengjiu Machinery Group) must strictly adhere to heat treatment parameters and conduct hardness uniformity testing during quality control to ensure long-term chain reliability.

How can I determine if a 3/8" SawChain is a low-vibration, low-kickback chain?

1. Geometric Inspection

Depth Gauge Shape: The depth gauge of a low-kickback chain features a special bevel or raised profile to limit cutting depth and reduce impact force.

Tooth and Tie Strap Design: Rounded or beveled teeth and a wider tie strap provide a larger cushion during cutting, minimizing vibration transmission.

Drive Link and Low-Profile: The drive link and tie strap of a low-profile chain are arranged at an angle, creating a larger gap between the tooth tip and the guide bar, thereby suppressing vibration and reducing kickback energy.

2. Anti-Kickback Structure

Anti-Kickback Teeth: Special anti-kickback teeth are located at the front of the sprocket teeth to prematurely cut power transmission if the guide bar tip contacts a hard object. Guardrails and Chain Brakes: The chain is equipped with right/left guardrails, a chain catcher, and a fast-response chain brake system to instantly stop the chain in the event of abnormal rebound.

Rounded or Chamfered Tooth Tips: Rounded tooth tips reduce impact strength when colliding with hard objects, further minimizing the risk of rebound.

3. Vibration Suppression

Material and Heat Treatment: Uniformly hardened high-alloy steel or hard chrome plating is used to enhance the impact resistance of the tooth tips and reduce vibration caused by material unevenness.

Balanced Design: The chain's overall mass is evenly distributed, with a reasonable mass ratio between the drive link and the lacing, minimizing vibration caused by centrifugal imbalance during operation.

Clearance: The minimal clearance between the sprockets and the guide plate absorbs impact energy during cutting, reducing vibration amplitude.

4. Practical Testing Methods

Chain Brake Stopping Time: A standard tester is used to measure the time from chain brake activation to complete chain stop. A value of 0.12s or less is considered acceptable for low rebound performance. Vibration meter measurement: Use an accelerometer or vibration meter to record the peak vibration of the chain while it is running. A chain with a peak value below the industry threshold (approximately 0.5g) is considered low-vibration.

Test cut angle assessment: Perform a bevel cut test on standard wood and record the rebound angle generated by the chain. An angle ≤ 30° is considered low-rebound.

English

English

中文简体

中文简体

русский

русский