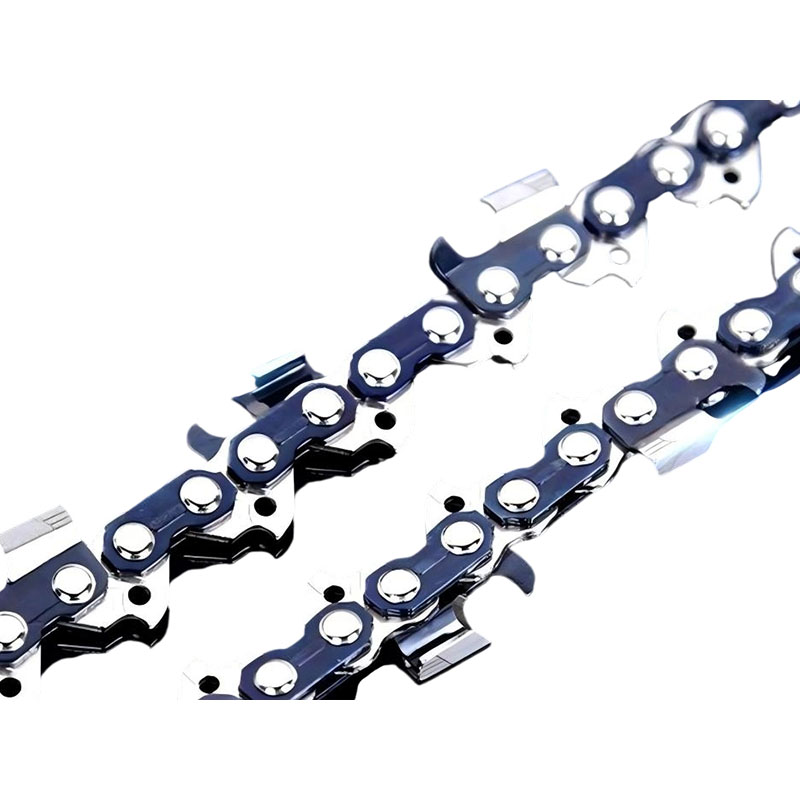

Correct Procedure for Adjusting the Tension When Installing 1/4" Saw Chains

1. Initial Inspection and Chain Positioning

Confirm that the guide bar is clean and free of debris; properly insert the chain onto the sprockets on both sides of the guide bar.

2. Coarse Adjustment of the Tension Nut

Turn the tension nut (or tensioning pulley) clockwise to slightly tighten the chain, avoiding significant slack.

3. "Snap Test" Precision Calibration (Critical Step)

Lift the chain to the center of the guide bar and observe the number of visible drive links.

Proper tension should result in the chain being slightly lifted in the center, with only three drive links visible. If more than three links are visible, tighten further. If the chain is snug against the guide bar and only one or two links are visible, loosen it slightly. This method has been proven to be a reliable field calibration method in chain saw tension adjustment research.

4. Fine-tune and Check for Free Rotation

Gently pull on both ends of the chain to confirm that the chain rotates smoothly and without binding along the entire length of the guide bar.

After completion, perform another snap test to ensure that the tension remains within the target range.

What guide bar diameters (bar diameters) are suitable for 1/4" saw chains?

Guide Bar Diameters Suitable for 1/4" Saw Chains

1. Recommended Range: 10–14 inches (approximately 254–356 mm).

2. Compatible Displacement: 28–32cc for chainsaw displacement, suitable for small to medium-sized chainsaws.

3. Selection Considerations:

Workload: For heavy-duty operations, a larger diameter (14 inches) is recommended for improved cutting stability.

Material Hardness: When cutting hardwood or metal, the guide bar diameter can be increased to reduce chain tension fluctuations.

Safety Tip: Using a guide bar with a diameter exceeding the recommended diameter can result in uneven chain tension, increased wear, and even the risk of chain derailment.

Key Points for Purchasing and Daily Maintenance

1. Check Chain Tension and Wear: Check the tension and observe the sprocket wear every 10–15 hours of use or after every 50 meters of cutting.

2. Regular Lubrication: Apply specialized chain oil evenly to the contact surfaces between the sprocket and chain links to maintain an intact lubricating film.

3. Cleaning and Rust Prevention: After operation, remove wood chips and oil stains and store in a dry environment to prevent rust.

4. Replacement Cycle: Replace sprockets promptly if they become noticeably blunt or if links become loose to prevent damage to the equipment due to chain failure.

5. Technical Support: Contact Hengjiu Machinery Group directly for specific machine chain specifications, tension adjustment guidelines, and after-sales service.

English

English

中文简体

中文简体

русский

русский