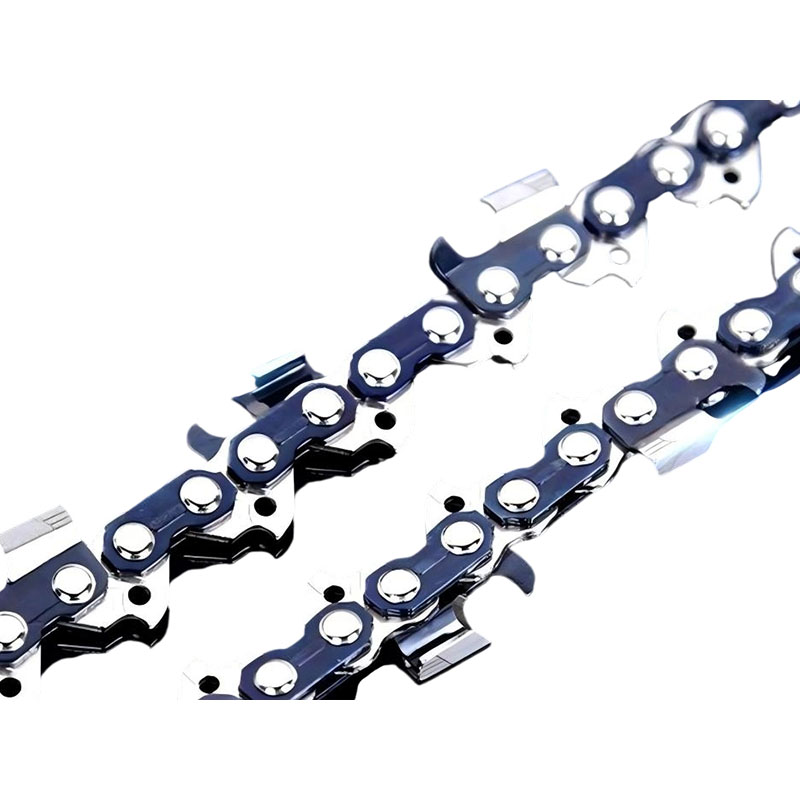

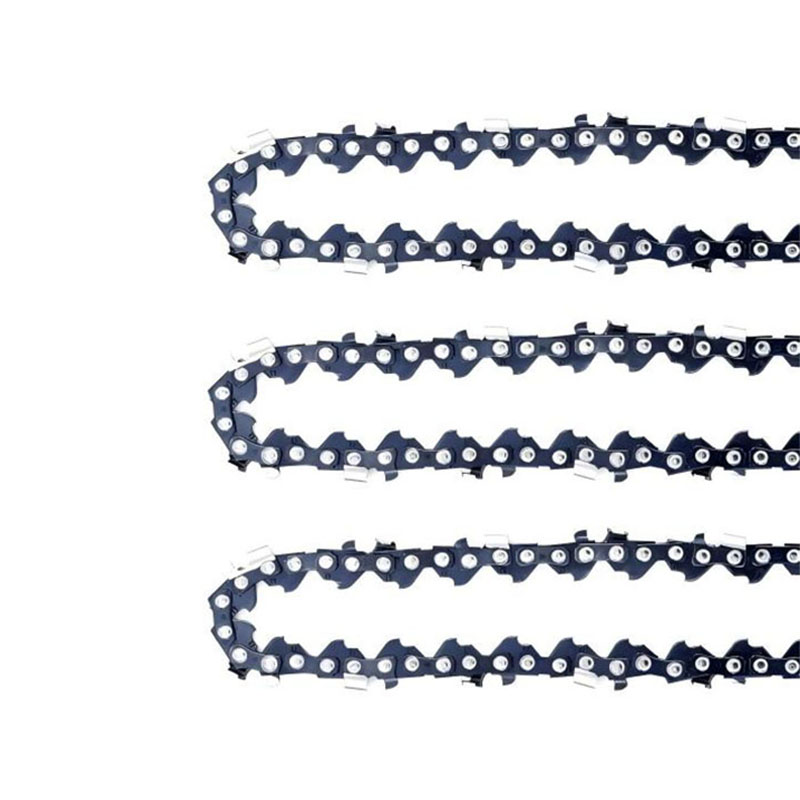

In modern forestry, wood processing, and biomass production, cutting efficiency is a key factor that directly influences productivity, operating costs, and equipment lifespan. Among the many variables affecting cutting performance, lubrication and chain tensioning stand out as two of the most critical yet often underestimated factors. For professionals relying on Chipper Saw Chains, understanding how these two elements interact can make the difference between smooth, high-output operations and frequent downtime caused by wear or failure.

Chipper Saw Chains are designed to withstand demanding cutting environments, including hardwood, softwood, frozen timber, and high-volume industrial applications. However, even the most advanced chain design requires correct lubrication and precise tensioning to reach its full potential. Improper practices not only reduce efficiency but also accelerate component fatigue, increase fuel consumption, and raise safety risks.

The Role of Lubrication in Chipper Saw Chain Performance

Why Lubrication Is Essential for Chipper Saw Chains

Lubrication serves as the lifeblood of Chipper Saw Chains. During cutting, the chain travels at high speed around the guide bar while engaging directly with wood fibers. This constant metal-to-metal and metal-to-wood interaction generates friction and heat. Without adequate lubrication, friction increases rapidly, leading to premature wear and energy loss.

- Reduces friction between chain links, guide bar, and sprocket

- Dissipates heat generated during high-speed cutting

- Prevents corrosion caused by moisture and wood sap

- Extends the service life of both chain and guide bar

Efficient lubrication ensures that Chipper Saw Chains maintain consistent cutting speed, stable tracking on the guide bar, and reduced resistance during operation.

Types of Lubricants Used for Chipper Saw Chains

Different operating environments require different lubrication solutions. Selecting the correct lubricant plays a vital role in achieving optimal efficiency.

- Mineral-based chain oils: Commonly used, cost-effective, and suitable for general forestry applications.

- Synthetic lubricants: Offer superior temperature stability and reduced oil throw-off at high chain speeds.

- Bio-based lubricants: Environmentally friendly options widely used in sustainable forestry operations.

For high-output industrial chipper systems, synthetic or bio-based lubricants often deliver more consistent performance, especially under extreme temperatures.

Impact of Poor Lubrication on Cutting Efficiency

Inadequate lubrication creates a chain reaction of performance issues. Friction increases cutting resistance, forcing the engine or motor to work harder. As a result, fuel or energy consumption rises, while cutting speed declines.

Common consequences of poor lubrication include:

- Overheating of Chipper Saw Chains

- Accelerated wear of chain rivets and cutters

- Guide bar discoloration and deformation

- Increased risk of chain seizure or breakage

Over time, insufficient lubrication can shorten chain life dramatically, increasing replacement costs and maintenance frequency.

The Importance of Proper Tensioning for Chipper Saw Chains

Understanding Chain Tension and Its Function

Chain tension refers to how tightly the Chipper Saw Chain fits around the guide bar. Correct tension ensures that the chain remains securely seated while still moving freely. Both over-tensioning and under-tensioning negatively affect cutting efficiency and safety.

A properly tensioned chain:

- Maintains stable contact with the guide bar

- Reduces vibration during cutting

- Improves cutting accuracy and consistency

- Minimizes wear on sprockets and bearings

Effects of Over-Tensioning Chipper Saw Chains

Over-tensioning is a common mistake, especially among operators who want to prevent chain derailment. While a tight chain may feel secure, excessive tension creates unnecessary resistance.

- Increased friction between chain and guide bar

- Higher energy consumption and reduced cutting speed

- Premature wear of drive links and bar rails

- Greater stress on crankshaft bearings and motors

In extreme cases, over-tensioned Chipper Saw Chains can overheat, leading to metal fatigue and unexpected failure.

Consequences of Under-Tensioning

Under-tensioned chains pose a different set of risks. A loose Chipper Saw Chain may whip, jump teeth, or derail entirely during operation.

- Inconsistent cutting performance

- Increased vibration and operator fatigue

- Higher likelihood of chain derailment

- Uneven wear on cutters and drive links

Efficiency drops as cutting becomes less controlled, and safety hazards increase significantly.

How Lubrication and Tensioning Work Together

The Interdependence of Lubrication and Tension

Lubrication and tensioning should never be treated as isolated factors. Their combined effect determines the overall efficiency of Chipper Saw Chains. A well-lubricated chain with incorrect tension will still perform poorly, just as a perfectly tensioned chain without sufficient lubrication will suffer rapid wear.

Key interactions include:

- Proper lubrication reduces friction, allowing optimal tension settings

- Correct tension ensures even oil distribution along the chain

- Balanced settings minimize heat buildup and mechanical stress

When both elements are optimized, Chipper Saw Chains deliver smoother cuts, higher throughput, and longer service intervals.

Performance Comparison: Optimized vs. Neglected Setup

|

Factor |

Optimized Lubrication & Tension |

Poor Lubrication or Incorrect Tension |

|

Cutting Speed |

Consistent and high |

Reduced and unstable |

|

Energy Consumption |

Lower and efficient |

Higher due to friction |

|

Chain Lifespan |

Extended service life |

Accelerated wear |

|

Safety Level |

Stable and controlled |

Higher risk of derailment |

Best Practices for Maximizing Chipper Saw Chain Efficiency

Lubrication Best Practices

- Check oil flow before each operation

- Use lubricants suited to temperature and wood type

- Clean oil ports regularly to prevent blockages

- Adjust oil output for high-speed industrial applications

Tensioning Best Practices

- Tension chains when cold, then recheck after warming up

- Ensure chain snaps back smoothly on the guide bar

- Inspect tension regularly during long cutting sessions

- Follow manufacturer guidelines for specific Chipper Saw Chains

Operational Environments and Their Influence

Hardwood vs. Softwood Applications

Hardwood cutting generates higher friction and heat, making lubrication especially critical. Softwood applications may allow slightly lower oil output, but tension accuracy remains equally important.

Cold and Hot Climate Considerations

In cold climates, thicker oils may restrict flow, requiring low-temperature lubricants. In hot environments, oil viscosity must remain stable to prevent excessive throw-off from fast-moving Chipper Saw Chains.

Maintenance and Long-Term Cost Efficiency

Consistent attention to lubrication and tensioning reduces downtime, lowers maintenance costs, and improves return on investment. Industrial operators often report significant savings when implementing structured chain maintenance routines.

Preventive maintenance strategies include:

- Scheduled inspections of oil delivery systems

- Routine chain and bar measurements

- Training operators on correct adjustment techniques

Frequently Asked Questions About Chipper Saw Chains

How often should Chipper Saw Chains be lubricated?

Lubrication should be continuous during operation. Oil levels and flow should be checked before each shift and monitored during extended cutting periods.

Can over-lubrication reduce efficiency?

Excessive lubrication may increase oil consumption and attract debris, but it rarely causes as much damage as insufficient lubrication. Proper balance is recommended.

How can correct tension be identified?

A correctly tensioned Chipper Saw Chain should sit snugly on the guide bar while still moving freely by hand, with no sagging beneath the bar.

Does chain tension change during operation?

Yes. Heat causes metal expansion, so tension should be rechecked after the chain reaches operating temperature.

Do different Chipper Saw Chains require different settings?

Yes. Chain pitch, gauge, and application type influence both lubrication needs and optimal tension levels.

Efficiency Starts with Precision

Lubrication and tensioning are not merely routine maintenance tasks; they are performance-defining factors that shape how effectively Chipper Saw Chains operate in real-world conditions. By understanding their influence and applying best practices consistently, operators can achieve higher cutting efficiency, improved safety, and extended equipment life across a wide range of forestry and industrial applications.

Content

- 1 The Role of Lubrication in Chipper Saw Chain Performance

- 2 The Importance of Proper Tensioning for Chipper Saw Chains

- 3 How Lubrication and Tensioning Work Together

- 4 Best Practices for Maximizing Chipper Saw Chain Efficiency

- 5 Operational Environments and Their Influence

- 6 Maintenance and Long-Term Cost Efficiency

- 7 Frequently Asked Questions About Chipper Saw Chains

- 8 Efficiency Starts with Precision

English

English

中文简体

中文简体

русский

русский