In forestry operations, landscaping, and professional wood processing, selecting the correct cutting components directly affects efficiency, safety, and equipment lifespan. Among these components, Chipper Saw Chains play a crucial role in determining cutting speed, surface finish, and overall performance. Different wood types—ranging from soft pine to dense hardwood—require different chain characteristics to achieve optimal results.

Understanding how Chipper Saw Chains interact with various wood materials allows operators to reduce wear, improve productivity, and lower long-term maintenance costs. The following guide explores how to choose the right Chipper Saw Chains for different wood types, with practical comparisons, selection tips, and frequently asked questions.

What Are Chipper Saw Chains?

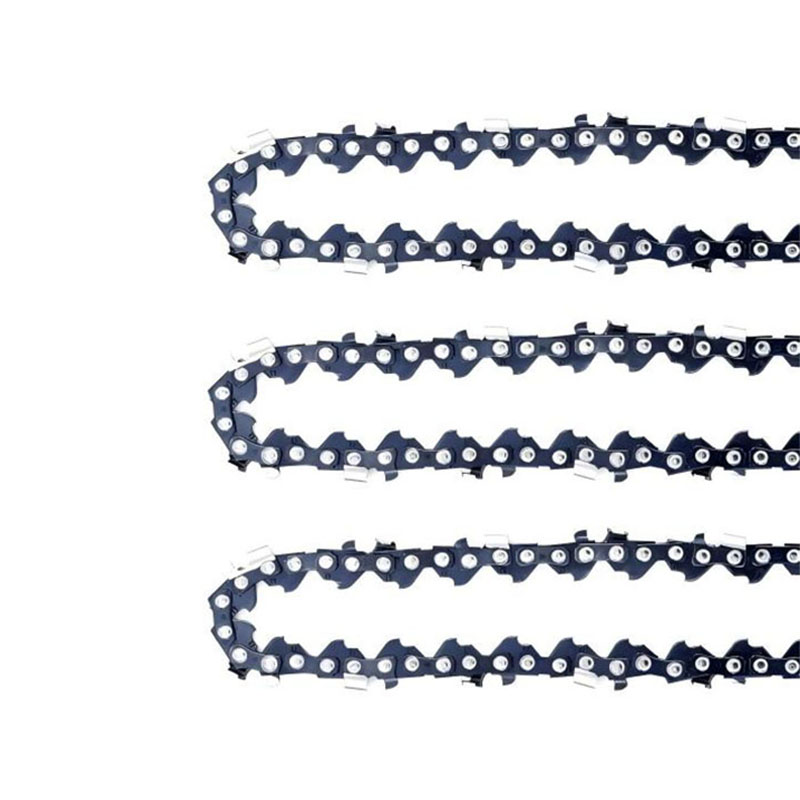

Chipper Saw Chains are a widely used chain type in chainsaws, harvesters, and wood processing equipment. They are characterized by rounded cutting corners and a semi-circular tooth profile, offering a balance between durability and cutting efficiency.

Key Characteristics of Chipper Saw Chains

- Rounded cutter edges for smoother operation

- High resistance to dirt, dust, and debris

- Easy sharpening and maintenance

- Stable performance across mixed wood conditions

These features make Chipper Saw Chains especially suitable for users who frequently encounter variable wood types or less-than-ideal cutting environments.

Why Wood Type Matters When Selecting Chipper Saw Chains

Not all wood behaves the same during cutting. Density, moisture content, resin levels, and grain structure significantly influence how a chain performs. Choosing inappropriate Chipper Saw Chains can result in slow cutting, excessive vibration, and accelerated chain wear.

Main Wood Properties Affecting Chain Performance

- Hardness:Hardwoods require stronger cutters and stable chain geometry.

- Moisture content:Green wood cuts differently than dry or seasoned wood.

- Resin content:Resinous woods can clog cutters and increase friction.

- Grain structure:Interlocked or twisted grain affects cutting smoothness.

Chipper Saw Chains for Softwood

Softwoods such as pine, spruce, fir, and cedar are commonly used in construction, packaging, and landscaping. These woods generally have lower density but higher resin content.

Recommended Features for Softwood Cutting

- Standard Chipper Saw Chains with rounded cutters

- Moderate chain pitch for faster chip clearance

- Anti-stick coating to reduce resin buildup

In softwood applications, Chipper Saw Chains provide smooth cutting with reduced kickback risk. Their rounded edges help maintain performance even when resin accumulates on the chain.

Performance Advantages

- Consistent cutting speed

- Lower vibration during extended operation

- Reduced sharpening frequency

Chipper Saw Chains for Hardwood

Hardwoods such as oak, maple, beech, and hickory are denser and more abrasive than softwoods. Cutting these materials places higher stress on saw chains.

Key Considerations for Hardwood Applications

- Hardened steel Chipper Saw Chains for wear resistance

- Optimized cutter depth gauges to control bite size

- Reinforced tie straps for structural stability

While chisel chains are sometimes preferred for pure hardwood cutting, Chipper Saw Chains remain a reliable choice when durability and control are prioritized over maximum cutting speed.

Chipper Saw Chains for Mixed Wood Conditions

In forestry and land clearing operations, equipment often encounters a mix of softwood, hardwood, and contaminated wood. This is where Chipper Saw Chains truly excel.

Why Chipper Saw Chains Perform Well in Mixed Wood

- Rounded cutters tolerate dirt and sand better

- Lower risk of sudden dulling

- Stable performance across changing materials

For operators who cannot predict wood type in advance, Chipper Saw Chains provide a balanced solution that minimizes downtime and maintenance.

Comparison: Chipper Saw Chains vs Other Chain Types

Chipper vs Full Chisel Chains

- Cutting Speed:Full chisel chains are faster in clean softwood

- Durability:Chipper Saw Chains last longer in dirty conditions

- Maintenance:Chipper chains are easier to sharpen

Chipper vs Semi-Chisel Chains

- Versatility:Chipper Saw Chains handle a wider range of wood types

- Smoothness:Reduced vibration during cutting

- Cost-effectiveness:Longer service life in mixed environments

How Chain Pitch and Gauge Affect Wood Cutting

Beyond cutter shape, pitch and gauge are critical parameters when selecting Chipper Saw Chains.

Chain Pitch Selection

- Smaller pitch: better control for light-duty cutting

- Larger pitch: increased cutting capacity for thick logs

Chain Gauge Considerations

- Thicker gauge improves stability in hardwood

- Thinner gauge reduces weight and improves maneuverability

Matching pitch and gauge to both the saw and wood type ensures optimal cutting performance and safety.

Maintenance Tips for Chipper Saw Chains

Proper maintenance extends the life of Chipper Saw Chains and ensures consistent cutting quality.

Best Practices

- Regular sharpening using correct file size

- Proper chain tension adjustment

- Frequent lubrication to reduce friction

- Inspection for damaged or cracked cutters

Well-maintained Chipper Saw Chains perform reliably across different wood types, reducing downtime and operating costs.

Safety Considerations When Cutting Different Wood Types

Wood density and grain affect kickback behavior and operator control.

Safety Advantages of Chipper Saw Chains

- Rounded cutters reduce aggressive biting

- Improved control during plunge cuts

- Lower kickback risk compared to sharp-corner chains

These characteristics make Chipper Saw Chains a preferred option for both professional operators and experienced users handling varied wood materials.

Frequently Asked Questions (FAQ)

Are Chipper Saw Chains suitable for hardwood?

Yes. Chipper Saw Chains can cut hardwood effectively, especially when durability, control, and resistance to contamination are required.

Do Chipper Saw Chains cut slower than chisel chains?

In clean, softwood conditions, chisel chains may cut faster. However, Chipper Saw Chains maintain performance longer in mixed or dirty environments.

How often should Chipper Saw Chains be sharpened?

Sharpening frequency depends on wood type and cutting conditions. In abrasive or dirty wood, more frequent sharpening is recommended.

Can one Chipper Saw Chain handle different wood types?

Yes. One of the main advantages of Chipper Saw Chains is their versatility across softwood, hardwood, and mixed wood applications.

Are Chipper Saw Chains beginner-friendly?

Their smooth cutting behavior and lower kickback tendency make Chipper Saw Chains suitable for operators seeking controlled and stable cutting performance.

Industry Outlook for Chipper Saw Chains

As forestry and wood-processing operations increasingly demand versatility and durability, Chipper Saw Chains continue to play a vital role in professional and industrial cutting applications. Their adaptability to different wood types makes them a reliable choice for modern cutting environments where efficiency and safety are equally important.

By carefully matching Chipper Saw Chains to wood characteristics, equipment specifications, and operating conditions, users can achieve consistent cutting results while extending chain service life and improving overall productivity.

Content

- 1 What Are Chipper Saw Chains?

- 2 Why Wood Type Matters When Selecting Chipper Saw Chains

- 3 Chipper Saw Chains for Softwood

- 4 Chipper Saw Chains for Hardwood

- 5 Chipper Saw Chains for Mixed Wood Conditions

- 6 Comparison: Chipper Saw Chains vs Other Chain Types

- 7 How Chain Pitch and Gauge Affect Wood Cutting

- 8 Maintenance Tips for Chipper Saw Chains

- 9 Safety Considerations When Cutting Different Wood Types

- 10 Frequently Asked Questions (FAQ)

- 11 Industry Outlook for Chipper Saw Chains

English

English

中文简体

中文简体

русский

русский