What is a Harvester Chain

1. Definition and Purpose

Harvester chain is a high-performance transmission component designed for agricultural machinery. It plays a key role in harvesters, ensuring the stable operation of machinery in high-intensity operations. As a harvester chain manufacturer, we are well aware of its importance in the agricultural field and are committed to providing customers with high-quality harvester chain products.

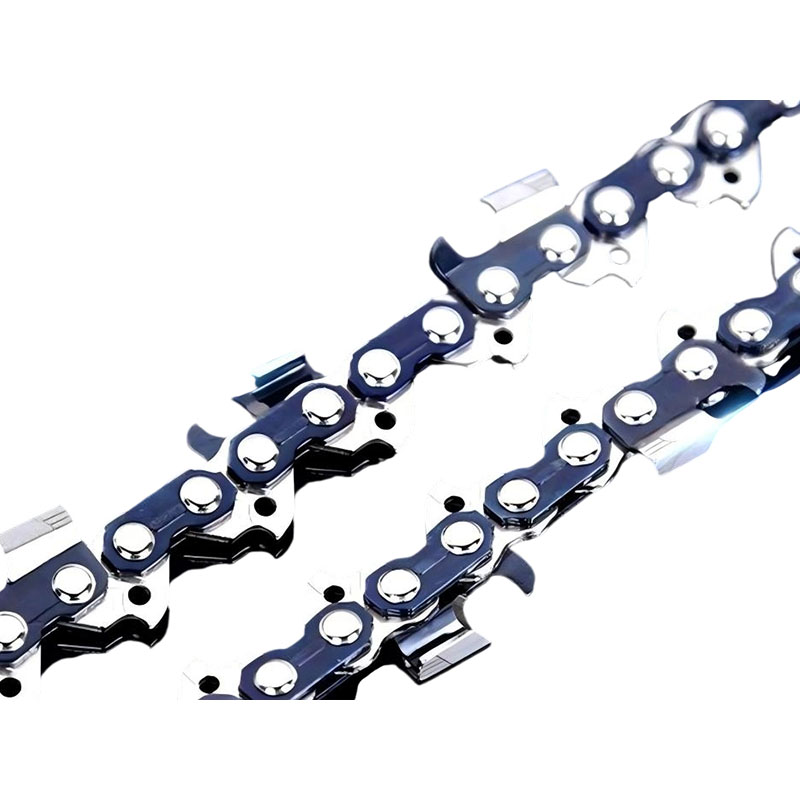

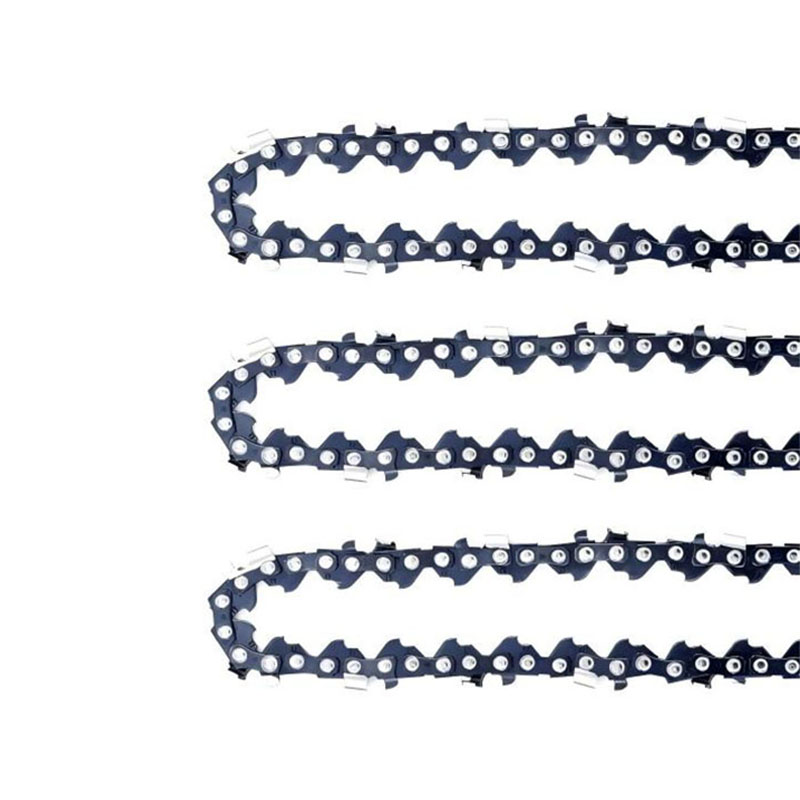

2. Structural Features

Harvester chain uses heavier components and sturdy connectors to withstand the high stress of mechanical harvesting. It ensures the stability and durability of the saw chain in high-intensity operations and reduces the risk of damage caused by excessive stress.

3. Materials and Treatment

The saw chain chassis is thickened and polished to make it less prone to breakage, improve durability and fracture resistance. This treatment enhances the strength of the saw chain, improves its surface finish, and reduces friction and wear.

4. Connector design

Using stronger cable ties and rivets can minimize the elongation of the saw chain even at the end of the saw chain life, minimizing unplanned downtime. Ensure the stability and reliability of the harvester chain in long-term use.

What is the heat treatment process of the harvester saw chain

1. Process Overview

The heat treatment process of the harvester saw chain is a key step to ensure its high performance and long life. As a harvester chain manufacturer, we use a unique heat treatment process to improve the hardness and toughness of the saw chain by precisely controlling the temperature and time. It can keep the harvester chain stable during high-intensity operations and reduce the risk of wear and breakage.

2. Temperature control

During the heat treatment process, we strictly control the temperature to ensure that the saw chain material is treated at the appropriate temperature. This precise temperature control can optimize the material structure, improve its hardness and toughness, and enhance the performance of the harvester chain.

3. Time control

By precisely controlling the time of heat treatment, we can ensure that the saw chain material stays at the appropriate temperature for a sufficient time to optimize the material structure. This time control can improve the fatigue resistance and corrosion resistance of the harvester chain, ensuring that it can operate stably in harsh working environments.

4. Effect verification

The heat-treated harvester chain has an optimized material structure, and its hardness and toughness are significantly improved. We ensure that each harvester chain meets high standards through rigorous testing and verification, providing reliable quality assurance.

Why is the cutting efficiency of the harvester chain high

1. Material selection

The high cutting efficiency of the harvester chain is mainly due to its unique design and high-quality materials. As a harvester chain manufacturer, we use higher-grade raw materials to ensure that the saw chain has excellent performance and durability in high-intensity operations.

2. Heat treatment process

By improving the heat treatment process, the material structure of the harvester chain can be optimized, and its hardness and toughness can be improved. It can keep the harvester chain stable during the cutting process, reduce the risk of wear and breakage, and improve cutting efficiency.

3. Cutting head design

The high-power cutting head design of the harvester saw chain can effectively improve the cutting speed and stability. It makes the harvester chain more efficient when cutting all kinds of wood, improving the working efficiency of logging machinery and the output of sawn timber.

4. Structural stability

The solid structure and anti-fracture ability of the harvester chain ensure stable operation in high-intensity continuous operation, reduce downtime and improve cutting efficiency. This structural stability enables the harvester chain to remain efficient and reliable during long-term use, meeting the needs of customers in the fields of agricultural machinery and logging machinery.

English

English

中文简体

中文简体

русский

русский