What is chainsaw chain

1. Definition and function

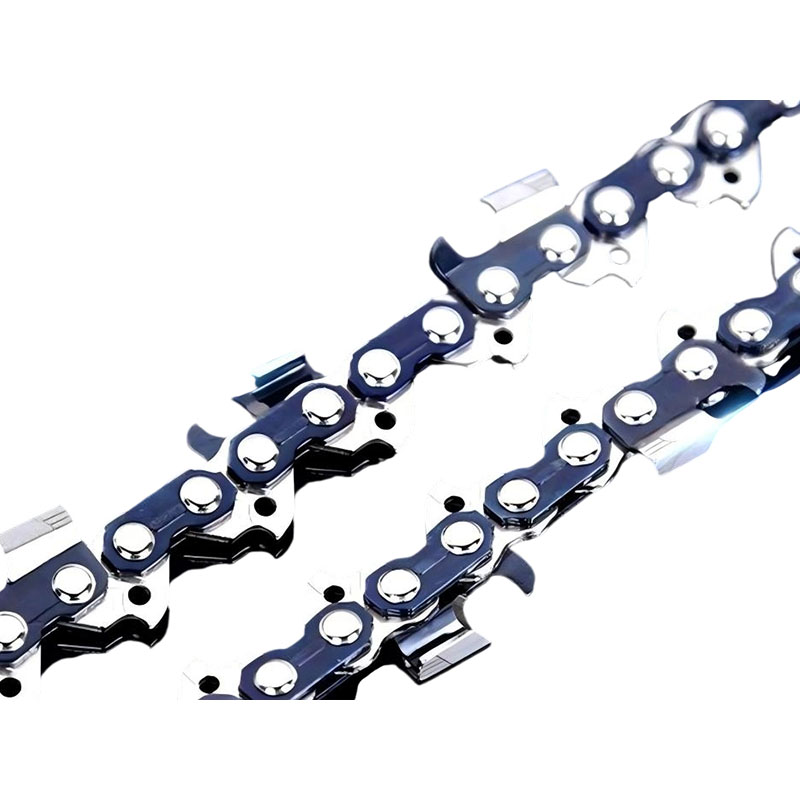

Core component of cutting tools: Chainsaw chain is the core component of chipper chainsaw chain, which consists of multiple links, each with cutting teeth for cutting wood and other materials. The design and manufacture of chainsaw chain directly affect its cutting efficiency and durability.

Multiple specifications and types: Chainsaw chain has a variety of specifications and types, including standard chipper chainsaw chain and professional-grade chipper chainsaw chain. Different specifications are suitable for different chipper chainsaw chains and cutting needs to meet various application scenarios.

High-quality materials: Chainsaw chain Manufacturer usually uses high-quality materials to ensure the strength and durability of the product. These materials undergo strict quality testing to ensure their purity and performance.

2. Manufacturing process

Precision forging and heat treatment: Chainsaw chain manufacturers use advanced manufacturing processes, including precision forging and heat treatment, to ensure the precision and strength of the chain. These processes can improve the durability and cutting efficiency of the chain.

Automated production line: The automated production line is used for production to ensure production efficiency and product quality. Automated production lines can reduce human errors and improve production efficiency and product quality.

Strict quality control: Chainsaw chain manufacturers usually carry out strict quality control, including raw material testing, production process monitoring and finished product inspection, to ensure the quality and performance of the products.

3. Application areas

Logging and wood processing: Chainsaw chain is widely used in the fields of logging and wood processing, providing efficient cutting performance. Whether it is ordinary logging or heavy logging, Chainsaw chain can provide reliable cutting results.

Agricultural machinery and construction machinery: Chainsaw chain is also suitable for chain drive systems in agricultural machinery and construction machinery, providing strong power transmission. In agricultural machinery and construction machinery, Chainsaw chain can provide reliable transmission performance and efficient cutting results.

Mining machinery and industrial applications: Chainsaw chain is also suitable for mining machinery and other industrial applications, providing high-strength transmission performance. In mining machinery and other industrial applications, Chainsaw chain can provide reliable transmission performance and efficient cutting results.

What is the cutting efficiency of Chainsaw chain

1. Design optimization

Chainsaw chain's chain link design, cutting tooth shape, and cutting tooth number are optimized to provide higher cutting efficiency, improve cutting speed and cutting effect, and meet different cutting needs.

2. Materials and processes

High-quality materials: Chainsaw chain is made of high-quality materials, which can provide higher cutting efficiency, improve the strength and durability of the chain, and reduce cutting resistance.

Advanced manufacturing process: Chainsaw chain is manufactured with advanced manufacturing process, which can provide higher cutting efficiency, improve the precision and strength of the chain, and reduce cutting resistance.

Strict quality control: Chainsaw chain manufacturers usually conduct strict quality control to ensure the quality and performance of the products. Strict quality control can improve the cutting efficiency and durability of the chain to meet the cutting needs of customers.

3. Application effect

Logging and wood processing: Chainsaw chain has high cutting efficiency in the fields of logging and wood processing. Whether it is ordinary logging or heavy logging, Chainsaw chain can provide efficient cutting effect to meet the cutting needs of customers.

Agricultural machinery and construction machinery: Chainsaw chain also has high cutting efficiency in agricultural machinery and construction machinery. In agricultural machinery and construction machinery, Chainsaw chain can provide efficient cutting effect and reliable transmission performance.

Mining machinery and industrial applications: Chainsaw chain also has high cutting efficiency in mining machinery and other industrial applications. In mining machinery and other industrial applications, Chainsaw chain can provide efficient cutting effect and reliable transmission performance.

How to maintain chainsaw chain

1. Regular cleaning

Use special cleaning agents: When cleaning chainsaw chain, special cleaning agents should be used to ensure that grease, sawdust and other impurities on the chain are thoroughly removed. It can keep the chain clean and sanitary and extend its service life.

Choose the right tools: Using special brushes and cleaning tools can more effectively clean each link and cutting tooth of the chainsaw chain. Ensure that the tools do not damage the chain and maintain its integrity and performance.

Thoroughly rinse: After cleaning, rinse the chainsaw chain thoroughly with clean water to ensure that all cleaning agents and impurities are removed. It can prevent the residue from corroding and damaging the chain.

2. Proper lubrication

Choose special lubricant: When lubricating the chainsaw chain, you should use special lubricant to ensure that the chain is fully lubricated and protected. Special lubricants can reduce friction and wear of the chain and improve its cutting efficiency and durability.

Apply evenly: When lubricating the chainsaw chain, you should ensure that the lubricant is evenly applied to each link and cutting tooth. It can keep the chain running smoothly and reduce cutting resistance and wear.

Lubricate regularly: Lubricate the chainsaw chain regularly according to the frequency of use and working environment. It can keep the chain in good condition and extend its service life.

3. Check the wear

Use special tools: When checking the wear of the chainsaw chain, you should use special tools and methods to ensure that wear problems are accurately discovered and handled. Special tools can help you measure the degree of wear of the chain more accurately.

Regular inspection: Check the wear of the chainsaw chain regularly according to the frequency of use and working environment. Can timely discover and deal with wear problems to prevent chain damage and accidents.

Timely replacement: When the wear of the chainsaw chain exceeds the safe range, a new chain should be replaced in time. Can keep the chain in good condition to ensure its cutting efficiency and safety.

4. Refer to the manufacturer's guide

Follow the maintenance guide: Chainsaw chain manufacturers usually provide detailed maintenance guides and suggestions to help customers properly maintain the chainsaw chain. Following these guidelines and suggestions can ensure that the chain is properly maintained and maintained.

Consult professional advice: If you encounter problems when maintaining the chainsaw chain, you can consult the professional advice of the chainsaw chainManufacturer. Targeted maintenance and maintenance suggestions can be provided according to your specific situation.

Refer to the chipper chainsaw chain manufacturer's guide: Chipper chainsaw chain Manufacturer will also provide corresponding maintenance guides and suggestions to help customers properly maintain the chipper chainsaw chain. Following these guidelines and suggestions can ensure that the chipper chainsaw chain is properly maintained and maintained.

English

English

中文简体

中文简体

русский

русский