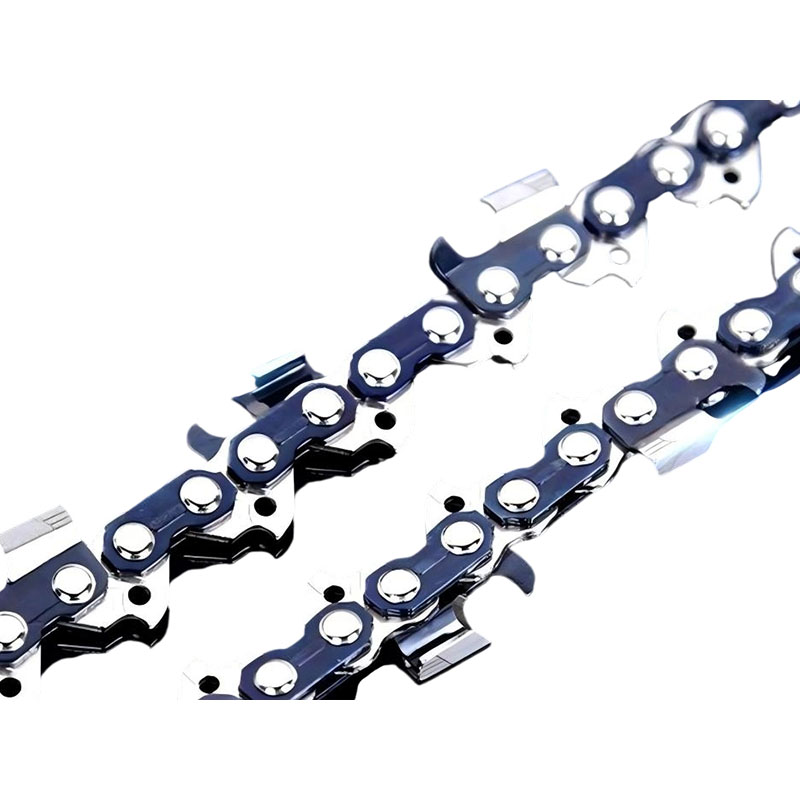

Blade design features

1. Optimized geometry design

Efficient cutting of wood fibers: The blade head of 325 saw chain adopts an optimized geometry design to ensure efficient cutting of wood fibers during the cutting process. It improves cutting efficiency and reduces resistance during cutting, making operation smoother.

Reduce cutting resistance: By accurately calculating and optimizing the geometry of the blade head, 325 saw chain Manufacturer and 325 saw chain factory ensure that the blade head can reduce resistance during cutting, improve cutting speed and efficiency.

Improve cutting accuracy: The optimized geometry design can also improve cutting accuracy, make the cutting surface flatter and smoother, and meet the user's requirements for cutting quality.

2. Specially treated damage resistance

Resistance to impact and wear: The blade head of 325 saw chain has been specially treated and has excellent resistance to damage. When cutting hard wood or encountering tree knots, the blade head can resist impact and wear, maintaining its sharpness and durability.

Maintain sharpness: This anti-damage design allows the 325 saw chain to maintain good performance during long-term high-intensity operations, ensuring that cutting efficiency and quality are not affected.

Extend service life: Through special treatment, the damage resistance of the cutter head has been significantly improved, extending the service life of the 325 saw chain and reducing the user's replacement cost.

3. Easy maintenance design

Easy sharpening and maintenance: The cutter head design of the 325 saw chain focuses on easy maintenance. The structure of the cutter head allows users to easily sharpen and maintain it, ensuring that the saw chain is always in the best working condition.

Extend service life: This easy maintenance extends the service life of the 325 saw chain and reduces the user's maintenance cost, allowing users to focus more on cutting operations.

Maintain optimal performance: Through regular sharpening and maintenance, users can ensure that the 325 saw chain is always in the best working condition, improving cutting efficiency and quality.

Maximize the function of the saw chain

1. Precisely calculated and optimized geometry

Efficient cutting of wood fibers: In order to maximize the function of 325 saw chain, 325 saw chain Manufacturer and 325 saw chain factory adopted precisely calculated and optimized geometry during the design process to ensure that the cutter head can efficiently cut wood fibers during the cutting process.

Reduce cutting resistance: By precisely calculating and optimizing the geometry of the cutter head, 325 saw chain Manufacturer and 325 saw chain factory ensure that the cutter head can reduce resistance during the cutting process, improve cutting speed and efficiency.

Improve cutting accuracy: The optimized geometry design can also improve cutting accuracy, make the cutting surface flatter and smoother, and meet the user's requirements for cutting quality.

2. Made of high-quality materials

Excellent wear resistance and impact resistance: The cutter head of 325 saw chain is made of high-quality materials with excellent wear resistance and impact resistance. This material can withstand long-term high-intensity operations and maintain good performance in various complex cutting environments.

Extended service life: By selecting high-quality materials, 325 saw chain Manufacturer and 325 saw chain factory ensure the durability and reliability of the saw chain, extending the service life of the 325 saw chain.

Reduced maintenance costs: The use of high-quality materials can also reduce the user's maintenance costs, allowing users to focus more on cutting operations.

3. Easy maintenance design

Easy sharpening and maintenance: The blade design of the 325 saw chain focuses on easy maintenance. The structure of the blade allows users to easily sharpen and maintain, ensuring that the saw chain is always in optimal working condition.

Extended service life: This easy maintenance extends the service life of the 325 saw chain and also reduces the user's maintenance costs, allowing users to focus more on cutting operations.

Maintain optimal performance: Through regular sharpening and maintenance, users can ensure that the 325 saw chain is always in optimal working condition, improving cutting efficiency and quality.

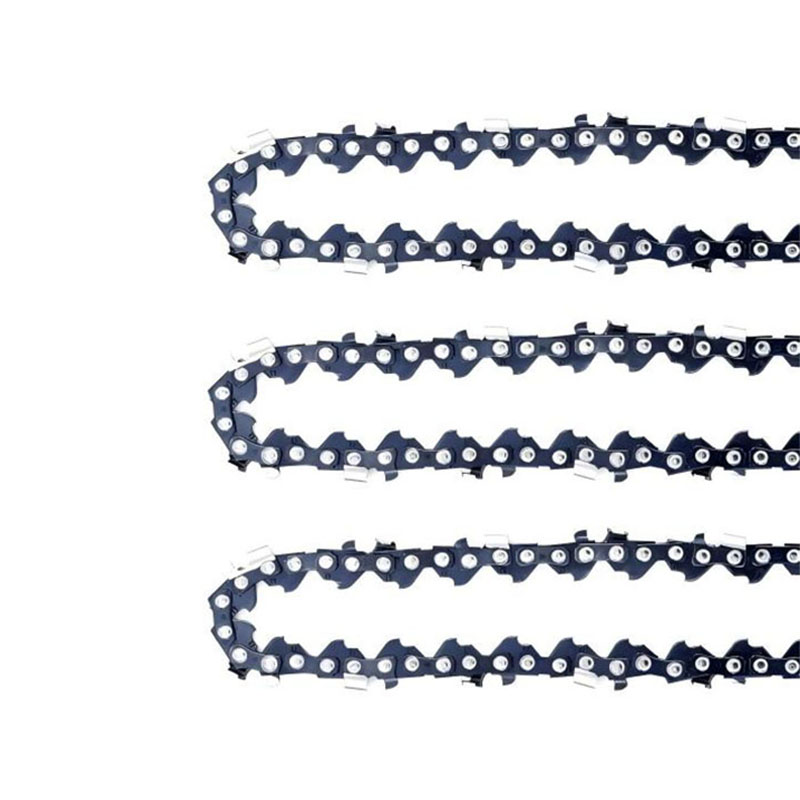

4. Overall design and manufacturing process

Precisely calculated pitch and specifications: In order to maximize the functions of the 325 saw chain, 325 saw chain Manufacturer and 325 saw chain factory also pay attention to the overall design and manufacturing process of the saw chain. The pitch and specifications of the saw chain are precisely calculated to ensure stable operation during the cutting process, reducing vibration and noise.

Optimized chain structure: The chain structure of the saw chain is optimized to ensure good performance during long-term high-intensity operations, improving cutting efficiency and quality.

Ensure stable operation: Through precise calculation and optimized design, 325 saw chain Manufacturer and 325 saw chain factory ensure that the saw chain can run stably during the cutting process, reduce vibration and noise, and improve the user's operating experience.

English

English

中文简体

中文简体

русский

русский