1. Prepare the appropriate tools

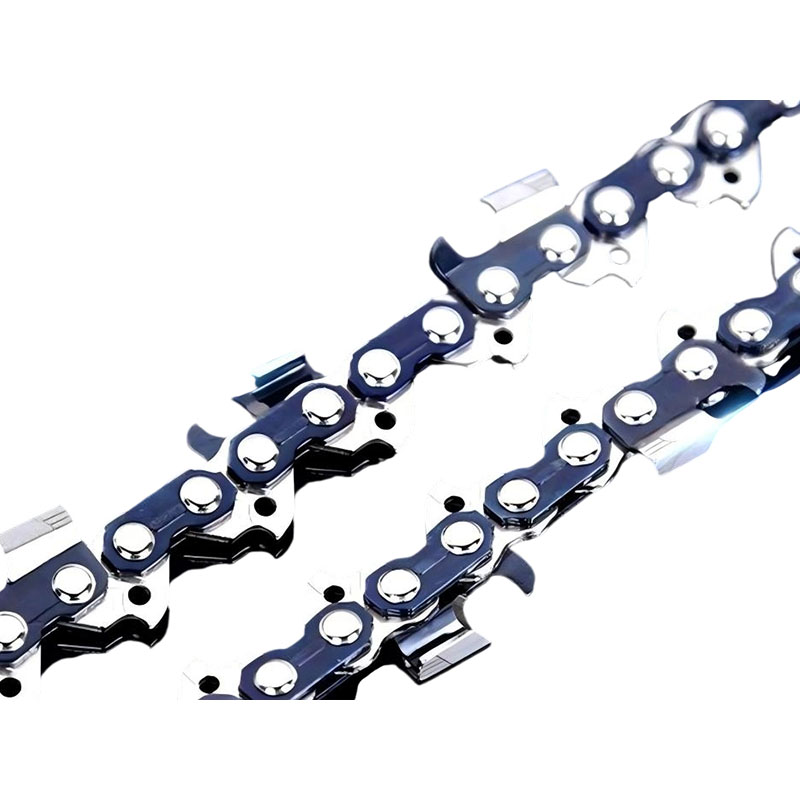

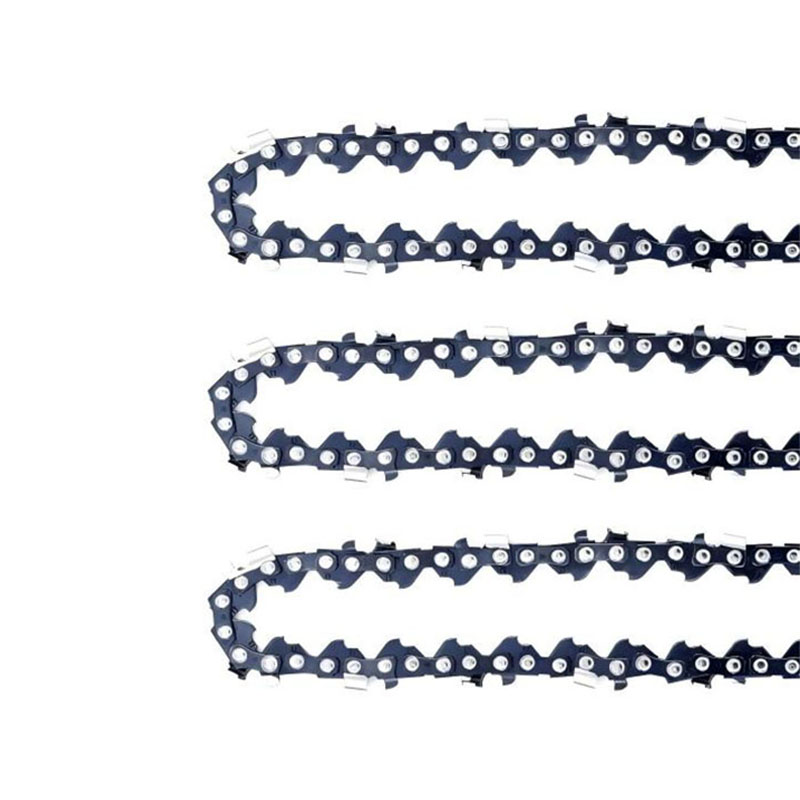

Select a dedicated .404" pitch, .063" thickness matching sharpener, using diamond or carbide grinding heads suitable for 68CrNiMo3 high-strength alloy steel.

Use a chain clamp or sharpening table to ensure the stability of the .404'' Saw Chain during sharpening.

2. Confirm the tooth type and set the grinding angle

Full-chisel: Grinding angle 30°-35°, symmetrical grinding on both sides.

Semi-chisel: Grinding angle 25°-30°, grinding only one side of the bevel.

3. Secure the chain and grind each tooth individually

Land the .404'' Saw Chain flat on the sharpening table, using a guide bar to ensure each tooth is accurately aligned with the sharpener.

Starting from one end of the chain, gently glide the sharpener, controlling the grinding depth between 0.005" and 0.010" to avoid over-removing metal.

4. Inspection and Fine-tuning

After sharpening, lightly touch the blade with your finger to confirm it is sharp and free of burrs.

Use calipers or a specialized measuring tool to check if the tooth height is uniform; make secondary fine-tuning if necessary.

5. Cleaning and Lubrication

Remove grinding debris with a brush or compressed air, then evenly apply chain oil to the chain to prevent rust.

English

English

中文简体

中文简体

русский

русский