1. High-quality material selection

.325" .050" SAW CHAIN uses high-strength alloy steel, which has excellent wear resistance and fatigue resistance. It can effectively resist the impact and friction in logging operations and extend the service life of the saw chain. Elements such as chromium, nickel and molybdenum are added to high-strength alloy steel, which improve the hardness and strength of the material and enhance its corrosion resistance and wear resistance. In actual use, this material can maintain stable performance in long-term high-intensity operations and reduce damage caused by material fatigue. The toughness and ductility of high-strength alloy steel also provide strong support for its damage resistance. When impacted by external force, this material can absorb part of the energy through plastic deformation, avoid damage caused by brittle fracture, and ensure the stability and reliability of the saw chain in complex environments.

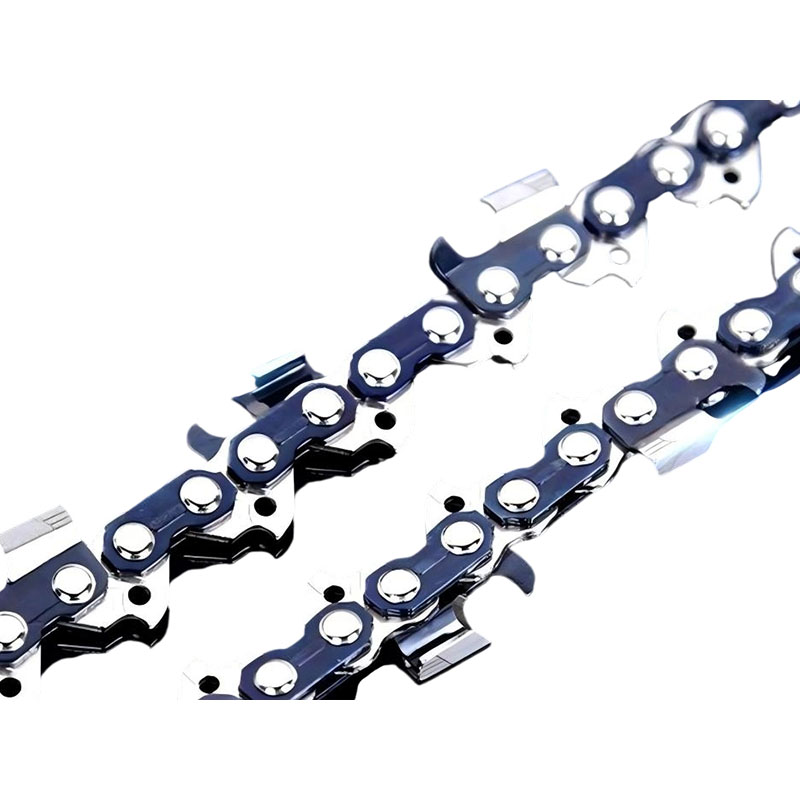

2. Unique cutter head design

The cutter head of .325" .050" SAW CHAIN has been carefully designed and optimized to maintain stable cutting force and reduce stress and vibration during cutting. The shape and angle of the cutter head are precisely calculated to ensure uniform cutting force when cutting wood, avoiding damage to the cutter head caused by uneven cutting force. This cutter head design improves the cutting efficiency of the saw chain, reduces the stress and vibration generated during the cutting process, and reduces the risk of wear and damage to the cutter head. The shape and angle of the cutter head can effectively disperse the stress generated during the cutting process, avoid damage caused by stress concentration, and maximize its cutting function. In actual use, this cutter head design can ensure that the saw chain maintains stable cutting performance during long-term high-intensity operations, meeting the needs of professional logging operations.

3. Advanced surface treatment technology

.325" .050" SAW CHAIN uses blueing treatment technology to form a dense protective layer on the surface of the cutter head, effectively preventing corrosion and wear. Blueing is a surface treatment process that can form a dense oxide film on the surface of the cutterr. This oxide film can effectively prevent corrosion and wear, and can improve the hardness and wear resistance of the cutter. In actual use, this protective layer can extend the service life of the saw chain, maintain the sharpness of the cutter, and ensure that it can maintain efficient cutting performance after long-term use. Blueing technology can improve the heat resistance and oxidation resistance of the cutter, maintain stable performance in high temperature environments, and enhance the damage resistance of the saw chain.

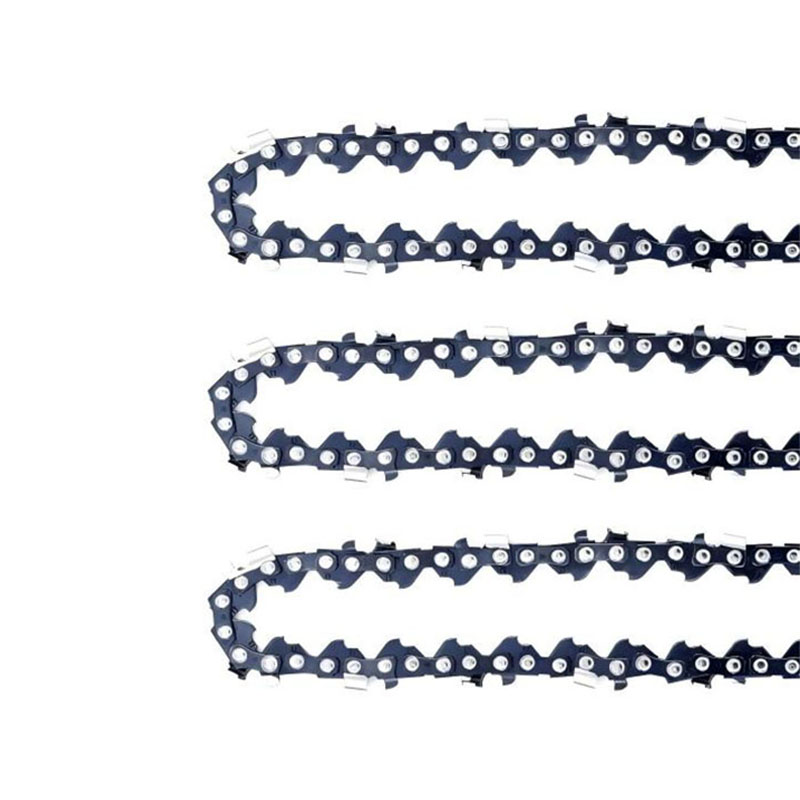

4. Optimized structural design

.325" .050" SAW CHAIN adopts a variety of sequence designs such as standard, half-skip and skip, which can effectively disperse the stress generated during the cutting process and avoid damage caused by stress concentration. This structural design improves the damage resistance of the saw chain and enhances its cutting efficiency and stability. In actual use, this structural design can ensure that the saw chain maintains a stable working state during long-term high-intensity operations, meeting the needs of professional logging operations. The drive link of the saw chain has also been optimized to withstand high-intensity workloads and ensure stable working conditions in various complex environments. This optimized design improves the saw chain's resistance to damage, enhances its durability and reliability, and enables it to maintain efficient working performance under harsh conditions.

English

English

中文简体

中文简体

русский

русский