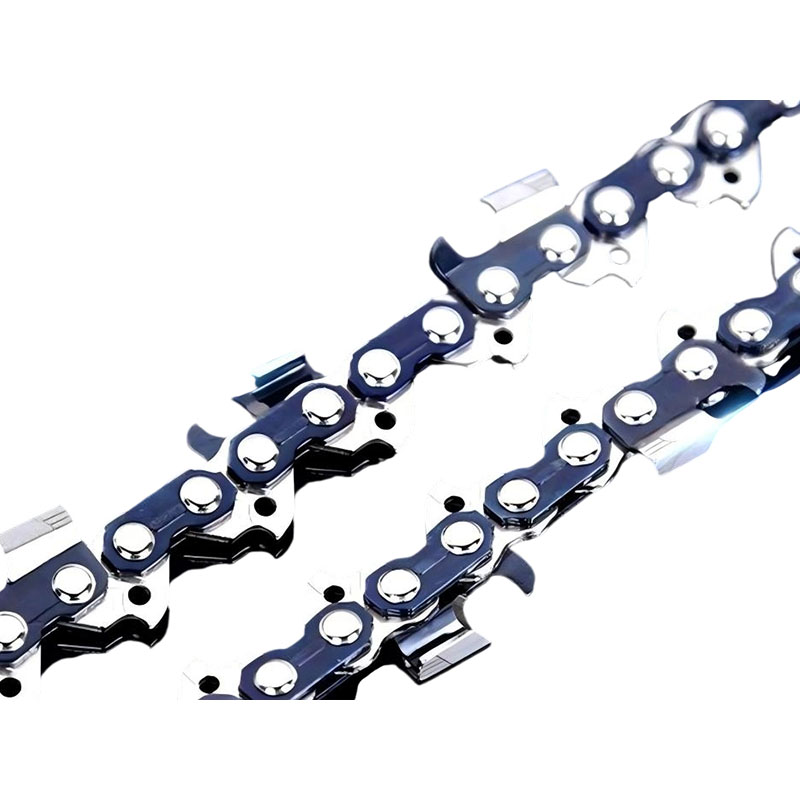

1. Principle of low-tooth design

The core of the low-tooth design of 3/8" Pitch LP Saw Chains lies in its unique tooth structure. Compared with standard saw chains, the low-tooth design has a flatter and rounder tooth shape. The saw teeth can distribute the cutting force more evenly when cutting wood, reducing the impact and tearing of wood. Due to the uniform distribution of cutting force, the wood fibers are less resisted when being cut, and the cutting process is smoother.

2. Achieve smoother cutting

The low-tooth design of 3/8" Pitch LP Saw Chains optimizes the geometry of the saw teeth, so that the saw teeth can cut in and out more effectively when cutting wood. The gentle bevel of the saw teeth reduces friction and resistance during cutting, and reduces vibration and noise during cutting. It allows 3/8" Pitch LP Saw Chains to remain stable during cutting, reduce the jitter and deviation of the saw chain, and achieve smoother cutting results.

3. Reduce kickback

Kickback is one of the common safety hazards of saw chains during cutting. It usually occurs when the 3/8" Pitch LP Saw Chains get stuck in the wood, causing the saw chain to suddenly rebound and cause harm to the operator. The low-tooth design reduces the possibility of the saw teeth getting stuck in the wood by optimizing the shape and angle of the saw teeth. The gentle bevel of the saw teeth makes it easier for the saw teeth to withdraw during cutting, reducing the risk of the saw teeth getting stuck in the wood. The low-tooth design can reduce the impact force during cutting and reduce the probability of kickback.

4. Improve safety and operating experience

Since the low-tooth design can achieve smoother cutting and reduce kickback, the operator can get a safer and more comfortable experience when using 3/8'' Pitch LP Saw Chains for cutting operations. The low-tooth design reduces vibration and impact during cutting, making the operator more stable and confident when using the saw chain. The low-tooth design can extend the service life of the saw chain, reduce the wear and damage of the saw chain, and reduce the frequency of maintenance and replacement of the saw chain.

The low tooth design is the key factor for 3/8" Pitch LP Saw Chains to achieve smoother cutting and reduced kickback. By optimizing the geometry and angle of the saw teeth, the low tooth design allows the saw teeth to distribute the cutting force more evenly when cutting wood, reducing friction and resistance during the cutting process, and achieving a smoother cutting effect. The low tooth design can reduce the risk of the saw teeth getting stuck in the wood, reduce the probability of kickback, and improve the safety and operating experience of the operator.

English

English

中文简体

中文简体

русский

русский