Harvester Saw Chains are a critical cutting component used in modern forestry machinery, especially in cut-to-length (CTL) harvesters. Designed to operate under extreme conditions, these chains play a vital role in felling, delimbing, and cross-cutting trees with high efficiency and precision. Unlike conventional chainsaw chains used by handheld equipment, Harvester Saw Chains are engineered for continuous industrial use, higher feed forces, and automated cutting systems.

As global forestry operations continue to shift toward mechanization, the performance, durability, and cutting accuracy of Harvester Saw Chains have become increasingly important. Understanding their structure, working principles, and advantages can help forestry professionals select the right chain for different harvesting conditions.

Understanding the Basic Structure of Harvester Saw Chains

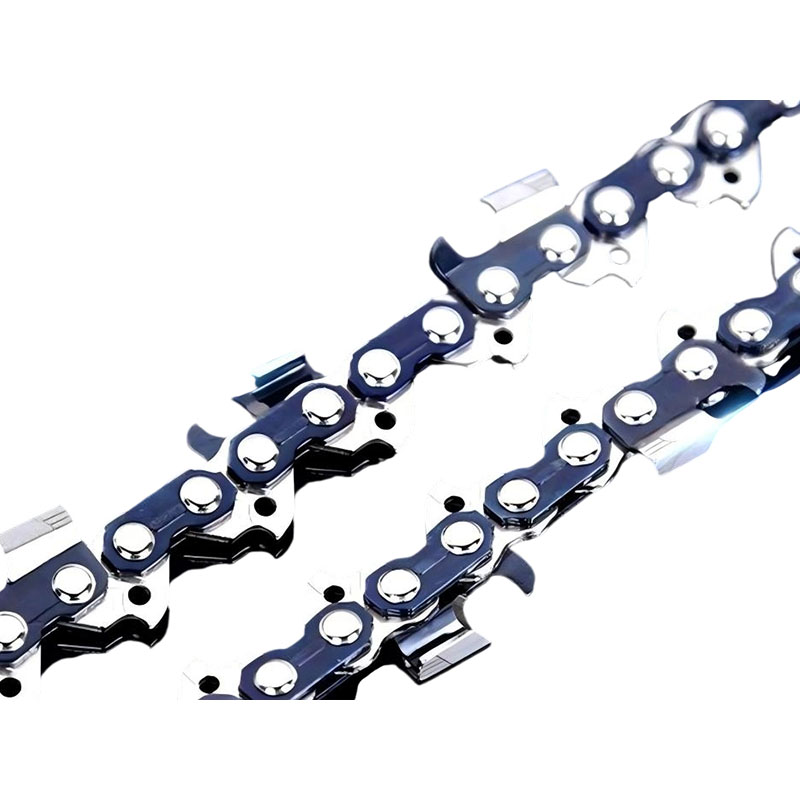

The design of Harvester Saw Chains reflects the demanding nature of mechanized logging. Each component is optimized for strength, stability, and consistent cutting performance.

Main Components of Harvester Saw Chains

- Cutting Teeth:Hardened teeth designed to withstand high-impact cutting and abrasive wood conditions.

- Drive Links:Connect the chain to the drive sprocket, ensuring smooth power transmission.

- Tie Straps:Provide structural integrity and flexibility to the chain loop.

- Rivet System:Reinforced rivets reduce chain stretch and improve long-term durability.

Compared to standard chainsaw chains, Harvester Saw Chains feature thicker gauge materials and reinforced links to handle higher torque and longer operating hours.

How Do Harvester Saw Chains Work in Forestry Machines?

Harvester Saw Chains operate as part of a fully integrated cutting system within a harvester head. Once the tree is gripped by feed rollers, the chain-driven guide bar cuts through the trunk while sensors and control systems regulate speed, pressure, and cutting length.

The Cutting Process Explained

- The harvester head grips the tree securely.

- The saw unit extends toward the trunk.

- Harvester Saw Chainsrotate at high speed along the guide bar.

- Cutting teeth remove wood fibers efficiently with minimal vibration.

- The chain retracts after completing the cut, preparing for the next operation.

This automated process ensures consistent cutting accuracy, reduced operator fatigue, and higher productivity compared to manual chainsaw operations.

Key Advantages of Harvester Saw Chains

The widespread adoption of Harvester Saw Chains in industrial forestry is driven by several distinct advantages.

High Durability and Long Service Life

Manufactured from heat-treated alloy steel, Harvester Saw Chains are built to resist wear, stretching, and breakage. This durability translates into fewer replacements and reduced downtime.

Enhanced Cutting Efficiency

Optimized tooth geometry allows faster penetration into wood, even in frozen, hardwood, or contaminated timber. This results in smoother cuts and improved fuel efficiency of the harvester.

Consistency and Precision

Automated cutting systems rely on stable chain performance. Harvester Saw Chains deliver uniform cutting depth and length accuracy, which is essential for meeting commercial timber specifications.

Harvester Saw Chains vs. Standard Chainsaw Chains

While both types of chains serve the same fundamental purpose, their design and application differ significantly.

Design and Construction Comparison

- Material Thickness:Harvester Saw Chains use thicker steel for higher load resistance.

- Tooth Profile:Designed for continuous cutting rather than intermittent manual use.

- Heat Treatment:Advanced hardening processes extend service life.

Performance Differences

Standard chainsaw chains are optimized for portability and ease of sharpening, while Harvester Saw Chains focus on productivity, automation compatibility, and long-term durability. In large-scale forestry operations, the latter significantly outperforms manual chains in terms of output and cost efficiency.

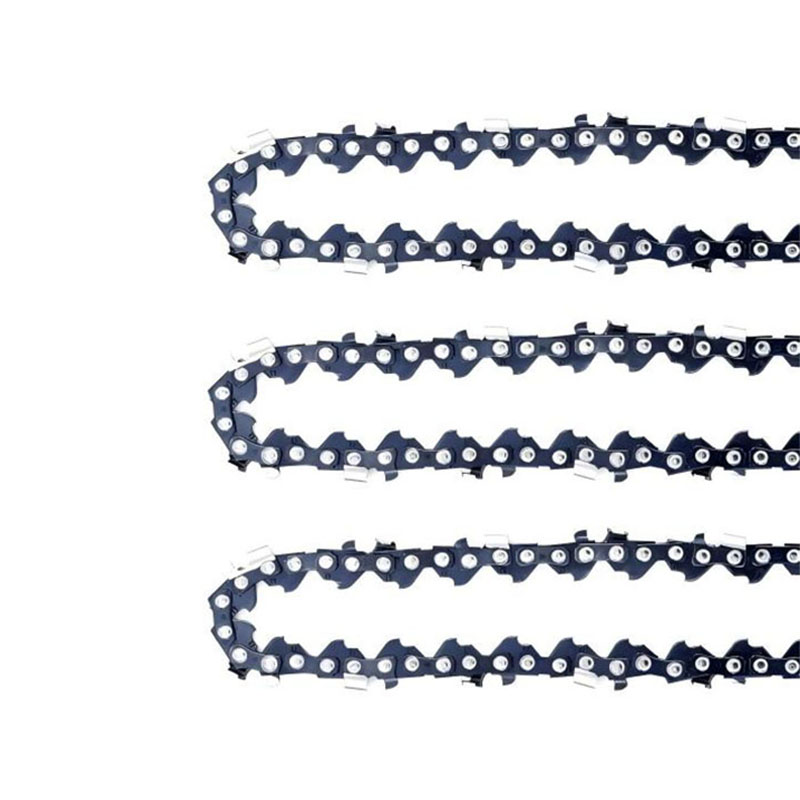

Types of Harvester Saw Chains

Different forestry environments require different chain configurations. Harvester Saw Chains are available in multiple designs to match specific cutting conditions.

Full Chisel Harvester Chains

Designed for high-speed cutting in clean wood, full chisel chains offer maximum efficiency but require precise maintenance.

Semi-Chisel Harvester Chains

With rounded cutting corners, semi-chisel chains perform better in dirty or frozen wood and maintain sharpness longer.

Low-Vibration and Reduced-Kickback Designs

These designs improve machine stability and reduce stress on the cutting system, especially during continuous operation.

Maintenance and Sharpening Best Practices

Proper maintenance is essential for maximizing the lifespan of Harvester Saw Chains.

Regular Inspection

- Check for uneven tooth wear

- Inspect rivets and drive links for cracks

- Monitor chain tension and alignment

Professional Sharpening

Most forestry operations use automated sharpening machines to maintain consistent tooth angles and depth gauges. Correct sharpening improves cutting speed and reduces fuel consumption.

Economic Impact of High-Quality Harvester Saw Chains

Although premium Harvester Saw Chains may have a higher initial cost, their long-term economic benefits are significant. Reduced downtime, fewer replacements, and higher cutting efficiency contribute to lower cost per cubic meter of harvested timber.

For large-scale forestry companies, chain performance directly affects profitability and operational sustainability.

Environmental Considerations in Modern Forestry

Efficient Harvester Saw Chains contribute to environmentally responsible forestry by reducing fuel consumption, minimizing waste, and ensuring precise cutting. Clean cuts promote better log utilization and reduce unnecessary damage to surrounding trees.

Future Trends in Harvester Saw Chain Technology

Ongoing innovation is shaping the next generation of Harvester Saw Chains. Manufacturers are investing in advanced coatings, improved alloy compositions, and optimized tooth geometry to meet the demands of modern forestry.

Smart monitoring systems that track chain wear and cutting performance are also emerging, allowing predictive maintenance and further improving operational efficiency.

Frequently Asked Questions about Harvester Saw Chains

How often should Harvester Saw Chains be replaced?

Replacement intervals depend on wood type, operating conditions, and maintenance quality. With proper care, chains can last significantly longer than standard chainsaw chains.

Can Harvester Saw Chains be used on manual chainsaws?

No. Harvester Saw Chains are specifically designed for mechanized harvester heads and are not compatible with handheld chainsaws.

What factors affect cutting performance?

Key factors include chain sharpness, correct tension, lubrication quality, and matching the chain type to the wood conditions.

Are Harvester Saw Chains suitable for hardwood?

Yes. Many Harvester Saw Chains are engineered specifically for hardwood and frozen timber, offering excellent durability and cutting efficiency.

How do Harvester Saw Chains improve productivity?

By delivering consistent, high-speed cutting with minimal downtime, Harvester Saw Chains enable harvesters to process more trees per shift while maintaining accuracy.

Why Harvester Saw Chains Are Essential for Modern Forestry

Harvester Saw Chains represent a cornerstone of mechanized logging technology. Their robust construction, efficient cutting performance, and compatibility with automated systems make them indispensable for today’s forestry operations. As demand for sustainable and efficient timber harvesting grows, the role of high-quality Harvester Saw Chains will continue to expand across global markets.

Content

- 1 Understanding the Basic Structure of Harvester Saw Chains

- 2 How Do Harvester Saw Chains Work in Forestry Machines?

- 3 Key Advantages of Harvester Saw Chains

- 4 Harvester Saw Chains vs. Standard Chainsaw Chains

- 5 Types of Harvester Saw Chains

- 6 Maintenance and Sharpening Best Practices

- 7 Economic Impact of High-Quality Harvester Saw Chains

- 8 Environmental Considerations in Modern Forestry

- 9 Future Trends in Harvester Saw Chain Technology

- 10 Frequently Asked Questions about Harvester Saw Chains

- 11 Why Harvester Saw Chains Are Essential for Modern Forestry

English

English

中文简体

中文简体

русский

русский